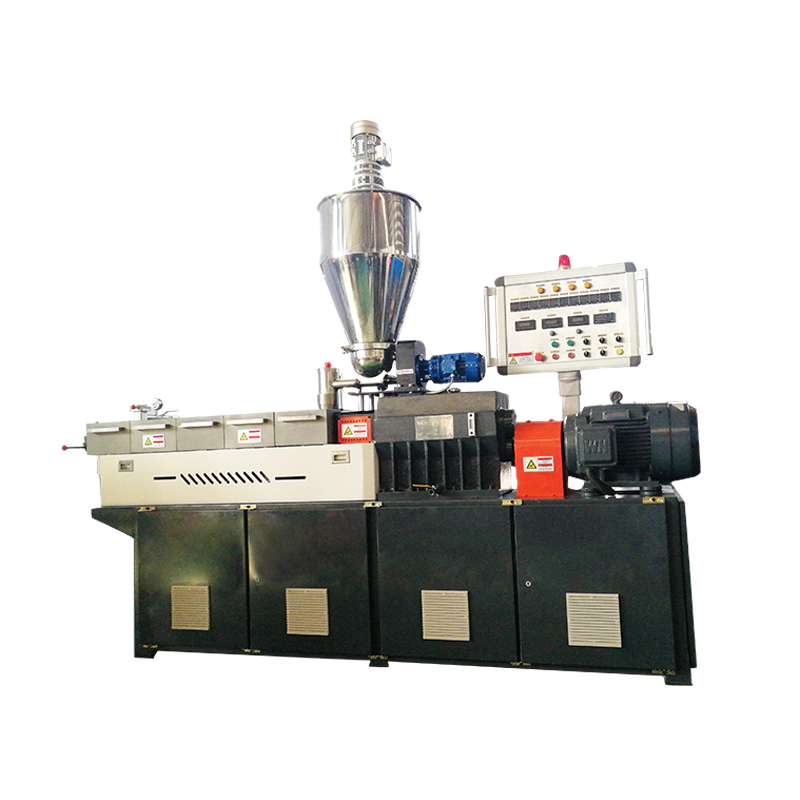

Masterbatch extruders are essential machines in the plastics industry, used to mix and process various materials. They allow for the incorporation of additives, colors, and other components into a base polymer. While these machines enhance production efficiency, safety is paramount when operating them. Understanding the potential hazards and implementing safety measures can prevent accidents and ensure a safe working environment.

Understanding the Risks

Operating masterbatch extruder involves several risks, including mechanical hazards, thermal hazards, and exposure to harmful substances. Mechanical hazards can arise from moving parts, which may cause injuries if proper precautions are not taken. Thermal hazards are present due to the high temperatures involved in the extrusion process. Additionally, operators may be exposed to dust and fumes from the materials being processed, which can pose health risks.

Personal Protective Equipment (PPE)

Wearing appropriate personal protective equipment (PPE) is crucial for anyone operating or working near masterbatch extruders. Essential PPE includes safety goggles to protect the eyes from flying particles, gloves to prevent burns and cuts, and respiratory protection to guard against inhaling harmful dust or fumes. Additionally, wearing heat-resistant clothing can help protect against thermal burns.

Training and Competence

Proper training is vital for all personnel involved in operating masterbatch extruders. Operators should be familiar with the machine’s functions, safety features, and emergency procedures. Regular training sessions can help reinforce safety protocols and ensure that operators are competent in handling the equipment. This training should also cover the potential hazards associated with the materials being processed.

Machine Maintenance and Inspections

Regular maintenance and inspections of masterbatch extruders are essential for safe operation. Operators should conduct routine checks to ensure that all safety devices, such as guards and emergency stops, are functioning correctly. Scheduled maintenance should be performed by qualified personnel to address any wear and tear, ensuring that the machine operates efficiently and safely.

Emergency Procedures

Establishing clear emergency procedures is critical for ensuring safety in the event of an incident. All operators should be aware of the emergency shutdown procedures and the location of emergency exits and equipment. Regular drills can help familiarize personnel with these procedures, ensuring a swift and effective response in case of an emergency.

Proper Material Handling

Handling materials safely is a significant aspect of operating masterbatch extruders. Operators should be trained in proper lifting techniques to avoid injuries. Additionally, materials should be stored correctly to prevent spills and contamination. Using appropriate containers and labeling materials can help ensure safe handling and minimize risks.

Ventilation and Air Quality

Maintaining proper ventilation in the workspace is essential for protecting operators from harmful fumes and dust. Adequate ventilation systems should be in place to ensure that air quality remains safe. Regular monitoring of air quality can help identify potential hazards and ensure compliance with safety regulations.

Understanding Machine Controls

Operators must have a thorough understanding of the machine controls and their functions. Familiarity with the control panel can help operators respond quickly to any issues that may arise during operation. Clear labeling of controls and providing easy access to operational manuals can aid in this understanding.

Reporting Hazards and Incidents

Encouraging a culture of safety includes reporting any hazards or incidents promptly. Operators should feel empowered to report unsafe conditions or near misses without fear of repercussions. This proactive approach can help identify potential risks and implement corrective actions before accidents occur.

Conclusion

Safety considerations when operating masterbatch extruders are vital for protecting personnel and ensuring efficient production. By understanding the risks, wearing appropriate PPE, receiving proper training, and following established safety protocols, operators can create a safer working environment. Regular maintenance, emergency preparedness, and effective communication are also crucial components of a comprehensive safety strategy. Prioritizing safety not only protects workers but also enhances overall productivity in the plastics industry.